Tel: +852 2134-9916

Fax: +852 3016-9839

HK Add:Room F 6/f Mega Cube,No.8 Wang Kwong Road,Kowloon,Hong Kong

Mainland Add: D1437,Xinhezuo Plaza,No.168 Taihua Street,Shijiazhuang,050000 Hebei,P.R.China

Canada Add:13571 Commerce Parkway Richmond, BC V6V 2R2,Vancouver,Canada

E-mail: dlc3721@gmail.com

Whatsapp/wechat:

+8613582102264Application:

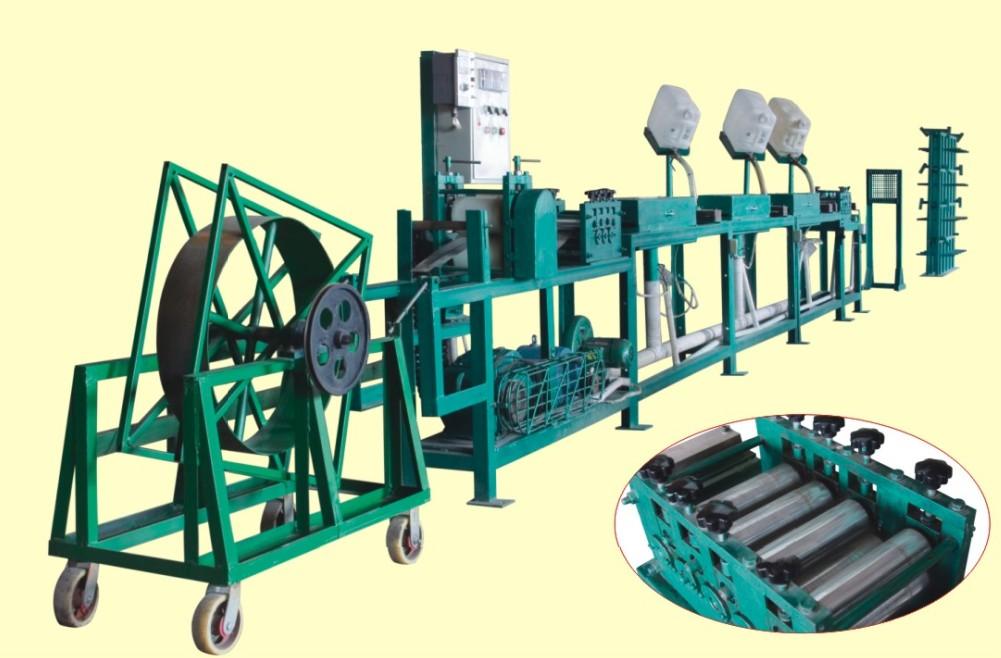

The machine is used to make office staples, furnature staples, carton staples etc.

with iron, steel and brass wires.

Staples production process:

select the raw materials (steel wire or stainless steel wire, iron wire or brass wires)

flattening the wire into flat wire with wire flattening machine

collating the flat wire together with wire collating machine

Forming the staple pins with staples forming machine

Packing the staples with cartons

The following machines are required to produce the staples.

1. Wire flattening machine

model: DLC-150

Specially made super strong alloy flattening wheel

flattening wire diameter:0.6-1.6mm

Flattening wire size tolorance/accuracy: ±0.005mm

flattening speed: 0-350meter/minute

motor power: 2.2kw

Staples forming machine

model:DLC120

Forming speed: 50-120 staples bands/min

staples band width: 80-127mm

staples band thickness: 0.4-1.35mm

motor power: 3.0kw

power supply: AC380V

Feature:

1. robust machine structure for long years service

2. the staples cutter and forming device has independant electrol control,

. they can be adjusted easily. the staples soulder and feet size can be adjusted

through regulating the feeding wire length and forming mould.

3. automatically eject the finished staples, if error ocurred, the machine will pause

automatically

4. the mould is made in high accuracy, installation and uninstallation can be made

quickly.

The plant area required(select one of the two):

1. premise/working shop: height at least 2.5m, length 17m, width 4m

2. premise /working shop: height at least 2.5m, length 20m, width 5m

the above workshop will include: raw materials storage, machine

prodution line area, finish product sorting and inspection area, packing area

and finish product warehouse.

WE HAVE THE MACHINE WORKING VIDEO, PLZ SEND EMAIL TO

chinadlc@qq.com for the video.

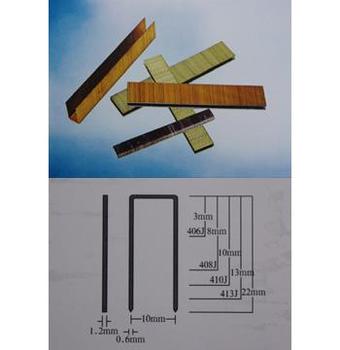

The made staples: